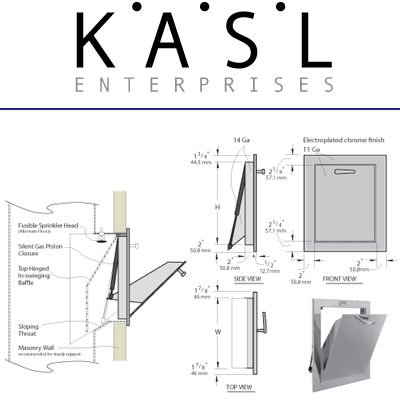

Trash Chutes

Laundry Chutes

Trash Compactors

A Message From The Owner

Kasl Enterprises is a small business located in a suburb of Detroit. Our primary business is providing & installing trash & laundry chutes made by Midland Chutes for new & renovated buildings. We’re also a capable supplier of trash compactors & compaction containers. The remainder of our business is providing spare parts, service work for chutes, and providing trash & laundry chutes that are installed by our customers.

Our business has doubled in size over the last few years because our prices are very competitive and we try to provide great customer service. Also - a number of options are available for trash & laundry chutes, and we save money for our customers by recommending only the options they need.

The majority of our customers are in the Midwest (Michigan, Ohio, Indiana, Kentucky, Tennessee, Illinois, Iowa, Wisconsin, and Minnesota), but we also provide & install chutes on a regular basis for projects in Colorado and in the South (from Texas to Florida). We also have repeat customers on both the East and West coasts.

Contact us if you need a chute for a project in the areas where we do business. Please tell us where your project is located in your email or voicemail. We will also consider projects in most other areas of the country, but we aren’t interested in projects in the Southwest or in big cities on the East or West coasts.

Click the button below to get our FREE guide: "Building the Right Chute: How to Plan for Commercial Laundry and Trash Chutes."

Thanks for reading this and for visiting our website.

Lee Gearig "The Chute Guy"

President and Owner

Kasl Enterprises

Email: kaslenterprises1@gmail.com

Office: (734) 699-3232 – Please leave a message.

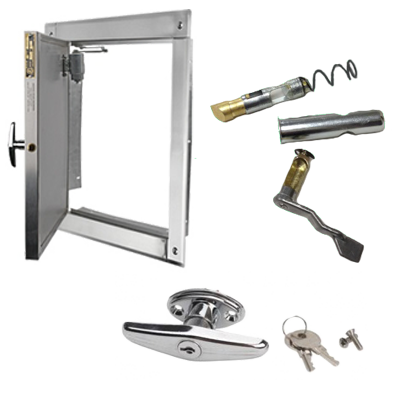

Trash & Laundry Chute Parts

If you need replacement parts or a new door, please send us an email with a picture of the part or door that needs to be replaced.